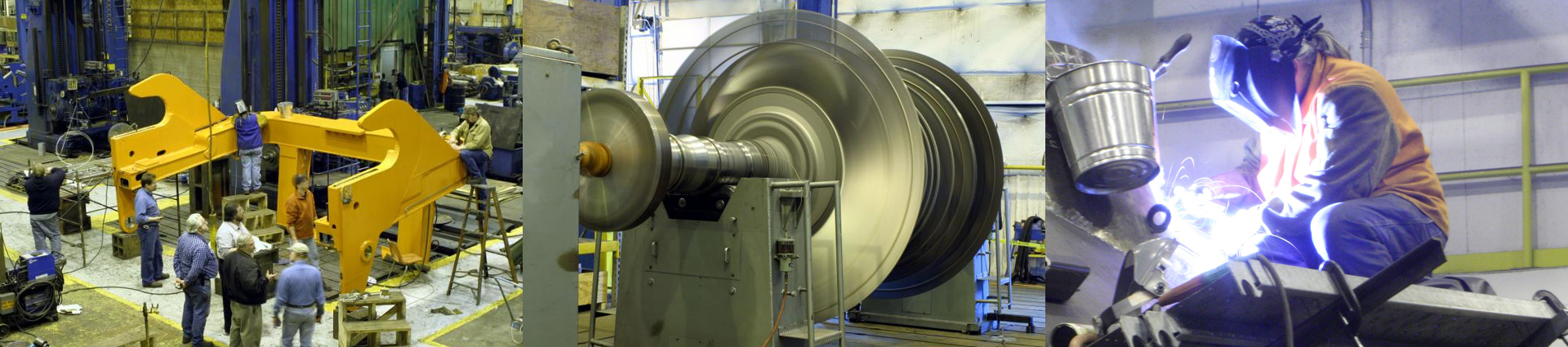

With our “State of the Art” Precision Manufacturing Division we are now your one source service provider.

Since 1972, Midwest Service Center (MSC) has defined “quality”, “responsiveness” and “best practices” in electrical and mechanical equipment services for a host of customers.

We offer a full range of manufacturing and service to Mining, Petrochemical, Power Generation, Steel and other process application needs.

Today, we continue to set the standard with unparalleled expertise and advanced in house capabilities ranging from inspection, testing and assembly. We perform large capacity manual as well as CNC machining that other service centers cannot. Vacuum pressure impregnation, laser, optical alignment and balancing. MSC is an answer for all your resource needs when planning or emergent tasks are on your agenda.

Midwest Service Center’s Featured Job

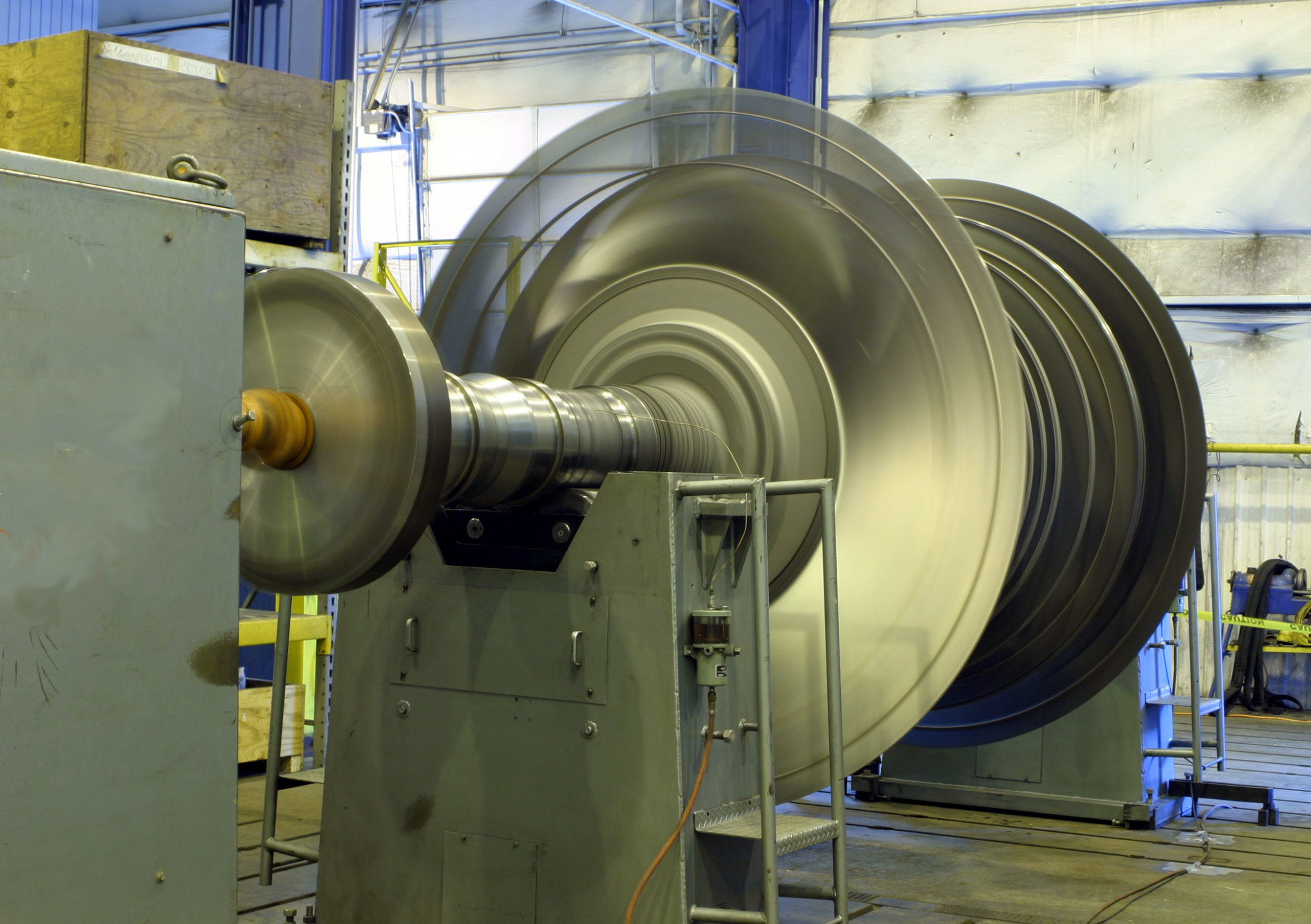

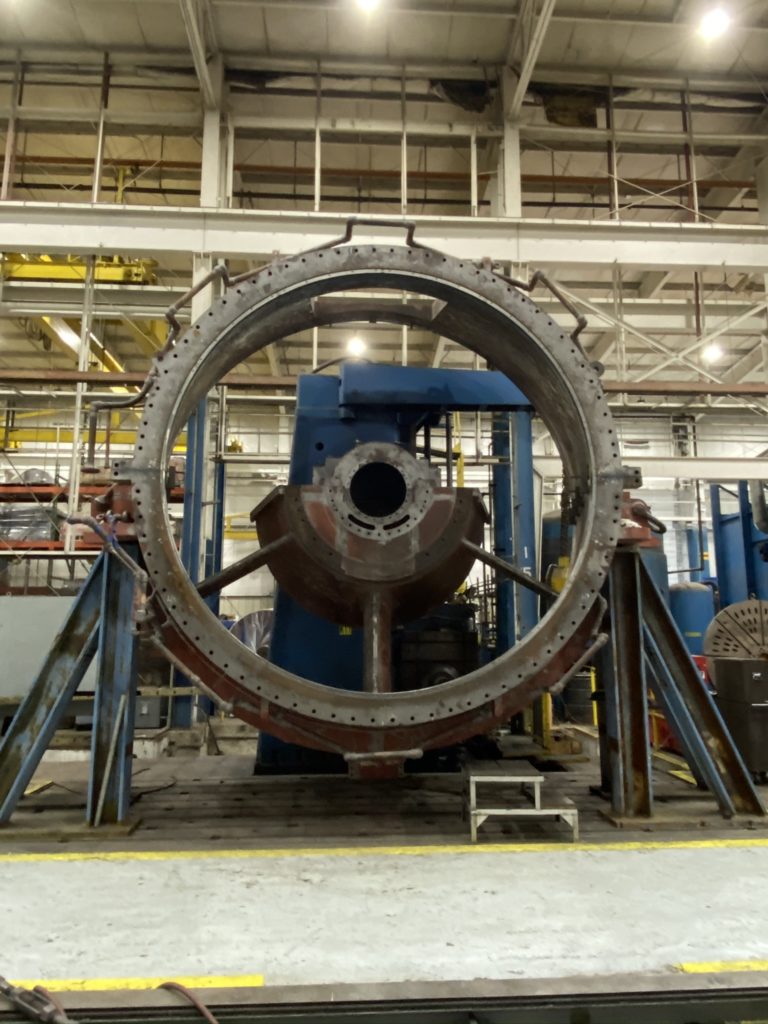

Ennis outage, a major overhaul was performed at Midwest Service Center during Summer/Fall of 2020. The Project involved inspection, fabrication, welding, Machining and final inspection of Large stationary steam turbine components. Exhaust Diffuser and LP cylinder with largest dimension of 17 feet; required welding, liner installation, in-line boring and welding. Two New Bearing Pedestal entailed ordering material, fabrication, welding, Stress Relief, Non-destructive examination and machining. Manufacturing new blades, liners and hardware for the project was another section of MSC scope. Schedule and resources were our challenges during this project. MSC utilized a customized portable boring machine for large diameter machining and qualified welders to support fabrication. MSC team completed the project with high Quality and Met customer’s expedited schedule.

Quoted sentences from Customer’s feedback email:

“You should be very proud of the dedicated group of experienced machinists and welders in the MSC shop. The Ennis replacement and repaired components were completed at MSC safely, high quality and close to the published schedules. The MSC new bearing pedestals were blue checked and scraped to the seating plates in record time due to the outstanding fabrication and machining in MSC.

Please thank the MSC team for a job well done.”

We take Great Pride in our Apprenticeship Program at Midwest Service Center

Employees at Midwest Service Center in our apprenticeship program constructed a panel saw in order to cut large 4-foot by 8-foot sheets of plywood to ultimately increase the speed of shipment processing. Cutting sheets of this size with a table saw can be rather time consuming and difficult for a single person. With the newly constructed panel saw, cutting plywood quickly and precisely is easier than ever. Being made out of extruded aluminum rails, the panel is lightweight and portable, but rigid enough to support heavy sheets. More importantly, this project has provided a learning experience for our younger machinists in training by manufacturing as many parts in house involved with the assembly. Machining the parts was achieved by using a CNC mill, water jet cutter, and manually operated lathe. The second image is a small engine crafted by John Wehner completed on Mazak 5 Axis.

We have a great group of young talent enrolled in our apprenticeship program where they are developing their talents and preparing for a promising workforce.

Special Thanks To:

Paul Szeliga | Engineering design & assembly.

Dan Titak | Machined mounting brackets & mounting plate on CNC mill.

Justin Meyer | Machined wheel sleeves on manual lathe & water jet mounting plate.

Our Quality

Customers have the peace of mind knowing that control plans are developed for every job, regardless of scope. All scheduling information, documentation and repair status indications are documented in a uniquely coded package. Electronic submissions are available upon request for job specific orders.

95% contract delivery and acceptance across all aspects of service. When margins run thin, Midwest Service Center helps you push the boundaries.

- ISO 9001:2015 Expiry 25 Oct 2024

- View our current ISO Certificate

- ANSI/ISO/ASQ Q9001

- LRQA registrar

- Compliant & Certified to standards

- Project Management

Our Mission

To improve and enhance the Quality of Life for our employees, thereby empowering them to set new benchmarks in our dedication to fulfill customer requirements through our continued commitment to defining Quality in Service.